Compliant Mechanism Explained

What's a Mechanism?

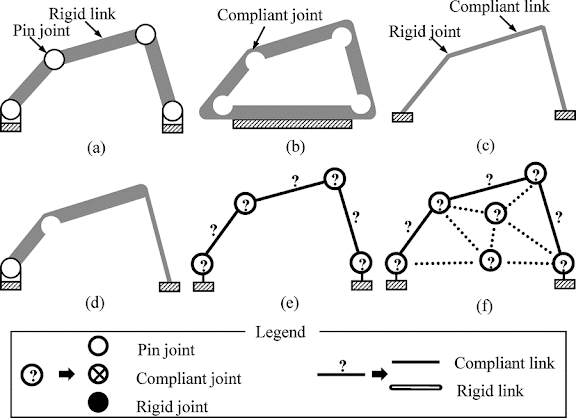

Mechanisms are mechanical devices that transfer or transform motion, force, or energy. Traditionally, rigid-body mechanisms consist of rigid links connected by movable joints.

Fig. Slider Crank Mechanism

What's a Compliant Mechanism?

Simply, compliant mechanisms are those that gain some mobility by deflection of flexible members rather than only by movable joints.

Some more definitions -

- A compliant mechanism is a structure, monolithic or quasi-monolithic, able to withstand external loads (thus keeping its shape) and, at the same time, flexible enough to enable morphing actions.

- Compliant (flexible) mechanisms are devices that use the elastic deformation of slender, spring-like portions, instead of classical rotation or sliding pairs to create, transmit, or sense mechanical motion.

Refer to (1:24 - 5.30) of the video below for more examples

and a better understanding...

Why use Compliant Mechanisms?

Some of the reasons why a compliant mechanism may be considered for use in a particular application are listed below :

- Productions Processes - The flexible regions of compliant mechanisms give them their motion, so planar sheets of material can readily be fabricated flat from compliant mechanisms.

- Performance - Compliant mechanisms have a smaller number of movable joints, such as a pin (turning) and sliding joints. This results in reduced friction and the need for lubrication. These are valuable characteristics for applications where the mechanism is not easily accessible, or for operation in harsh environments that may adversely affect joints.

- Reduced Number of Parts - Compliant mechanisms offer the benefit of dramatically reducing the number of parts required to achieve a given task. In order to reduce the part count, flexible parts can be used instead of springs, pins, and rigid hinges. When compared to a rigid version of the same mechanism, the number of components required for a compliant version is significantly lower.

- Precise Motion - Backlash and wear can reduce or eliminate precision in traditional mechanisms. Compliant mechanisms allow precise motion by reducing or eliminating backlash and wear. Mechanical wear occurs when parts rub against one another as they move. Rigid-body mechanisms get their motion from physical pins and hinges sliding against one another. As a result, the material gradually rubs away, altering the geometry and movement of the mechanism. The wear of compliant mechanisms can be greatly reduced since they use bending material instead of traditional pins and rigid hinges.

The video below briefly discusses the advantages of Compliant Mechanisms

Based on the methods used and types of mechanisms created, current compliant mechanism design techniques can be divided into three categories :

- Flexural pivot-based compliant mechanisms

- Flexible beam-based compliant mechanisms

- Fully compliant

- Flexural Pivot-Based Compliant Mechanism - This type of mechanism has narrow sections that connect relatively rigid segments, so compliance is concentrated in a few parts of the mechanism. They are usually monolithic in construction and can be designed either systematically based on existing rigid-body linkages or intuitively conceived linkages. Therefore, the joints are mostly flexible in this type, connecting rigid links together.

- Flexible Beam-Based Compliant Mechanisms - Since the slender beam-like segments are designed to undergo large deformations, flexible beam-based compliant designs extend their range of motion. In contrast to flexural pivot-based designs, flexible beam-based designs have a distributed compliance distribution, whereas they are not always monolithic construction, as they may include rigid segments and kinematic joints.

Design of Compliant Mechanisms

In order to design a compliant mechanism, the first step is to create a kinematically functional design based on prescribed input forces that produce the desired output motion. It is known as topological synthesis. The size and shape of individual elements can be optimized to a certain extent at this stage, but local constraints like stress and buckling cannot be imposed during this stage. During the next stage of size and shape optimization, performance constraints can be imposed once a feasible topology has been established.

Starting with functional specifications, the General Design procedure involves systematic methods for designing compliant mechanisms. Based on the desired input forces and output displacements, we can derive the topology of a compliant mechanism. Following that, we optimize the sizes and shapes of various elements of the compliant mechanism to satisfy prescribed mechanical or geometric advantages, stress constraints, and size constraints.

Topology Synthesis - This involves generating a feasible topology from input/output force/motion specifications to create a functional design.

Size and Shape Optimization - The system must meet performance requirements such as maximum stress, motion amplification, and force amplification.

Do Compliant Mechanisms have drawbacks?

It is difficult to analyze and design compliant mechanisms due to the relative difficulty associated with mechanism analysis methods and flexible member deflections. To combine these two bodies of knowledge in compliant mechanisms, it is necessary not only to understand both of them but also to understand their interaction in a complex system. Due to large deflections of the flexible members, linearized beam equations are no longer valid.

#MyOpinion

As complaint mechanisms are still in their infancy, there is still much need to be done in terms of research and quality work in terms of the fabrication of appropriate materials and designing flexible linkages. On the plus side, some of the brightest minds in the country are working on expanding their applications in this field.

compliant mechanisms will surely have widespread applications in future

ReplyDeleteConsidering the features Compliant Mechanisms have as mentioned, it can be applied in various fields making a noteable contribution.

ReplyDeleteNice information about compliant mechanism.

ReplyDelete